We are experts in

Precision CNC Machining

Our precision CNC machine shop in Anaheim, California, is known for meeting the exacting standards demanded by the aerospace, medical, defense, and renewable energy industries. We utilize several CNC-powered multi-axis machines to produce metal parts and components to the tightest tolerances with a careful eye on accuracy, timeliness, and reliability.

Pinnacle Precision commits time and resources to stay at the forefront of precision CNC machining. We continue to add capabilities and tools to our 73,000-square-foot facility to meet customer demand.

MACHINING CAPABILITIES

Precision CNC machining capabilities

Pinnacle Precision excels in High-Volume CNC Machining, delivering thousands of precision-engineered components daily. Our advanced machinery and skilled teams ensure consistent quality and efficiency, meeting our clients’ demanding production schedules.

Our CNC Routing capabilities deliver unparalleled precision in cutting and shaping various materials. Advanced routing technology allows Pinnacle to manufacture complex parts with high accuracy.

The CNC Turning center at Pinnacle enables the fabrication of precision parts via advanced lathes. We work with a variety of materials to achieve superior geometries and tolerances.

With cutting-edge technology, Pinnacle offers CNC Milling services for complex 3D shapes and intricate components. Our milling capabilities allow for precision production of parts with tight tolerances, serving diverse applications from prototype to high-volume production.

The tools we use for

Precision machining

The 73,000-square-foot advanced manufacturing facility at Pinnacle features several CNC-powered multi-axis machines that power our precision machining capabilities.

-

(2) 5-axis CNC machining center

-

(6) 3-Axis CNC machining centers

-

(1) CNC turning center

how we deliver

The Pinnacle CNC machining process

Each project coming into our Southern California headquarters receives maximum attention and care from the Pinnacle Precision team. It starts with our Customer Support team, which excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Pinnacle offers high-quality, high-volume CNC machining, routing, turning, and milling capabilities to meet demanding customer specifications.

Finishes & Treatments: We provide a range of finishes, including vibratory and barrel-type deburring, line graining, cyclone bead blasting, and more, to enhance the product’s appearance and performance.

Prototype to Production: Our team is adept at turning prototypes into high-quality, mass-produced components and assemblies, optimizing for efficiency and precision at every stage.

Manufacturing: Pinnacle’s Production team leverages the power of CNC laser cutters and punch presses to fabricate precision sheets sent to our machining, forming, bending, and welding crews. From there, our Finishing and Assembly teams handle electromechanical assembly, hardware installation, and seal applications before our Quality team inspects the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

a question we get:

What are the benefits of multi-axis machines in sheet metal machining?

Multi-axis machining centers, like the ones on the Pinnacle Precision production floor, are essential in fabricating precision sheet metal parts because they offer our Production team greater accuracy, flexibility, and efficiency.

There are many benefits to customers when they work with a manufacturing partner who uses multi-axis machines, including:

Higher Productivity: Multi-axis machines give manufacturers the ability to access multiple sides of a part without repositioning, reducing idle time and maximizing machine efficiency

Improved Quality: The precision of these machines produces parts with tighter tolerances and better surface finishes.

Increased Efficiency: More accurately machined parts equals less reliance on secondary operations like grinding, sanding, and polishing.

Reduced Set-Up Time: CNC programming enables a one-time set-up of a multi-axis machine, reducing re-set downtime found in traditional machining methods.

Competitive Advantage: The precision, accuracy, and reliability of parts and components produced via multi-axis machines offer manufacturers better parts, components, and assemblies.

Multi-axis machines accurately and efficiently perform cutting, punching, machining, forming, drilling, milling, tapping, and threading operations.

Pinnacle utilizes several multi-axis machines to produce sheet metal parts and components with complex designs for our customers in the aerospace, defense, medical, and renewable energy industries.

frequently asked questions

Our CNC machining capabilities extend to a wide variety of materials, including but not limited to aluminum, various alloys of steel, stainless steel, plastics, and nylon.

We leverage state-of-the-art CNC machinery, precision inspection capabilities, CMM technology, comprehensive quality control measures, and a highly skilled team to ensure that every part meets rigorous standards. Our facilities are AS9100, ITAR, and ISO 9001:2015 certified, reflecting our commitment to quality.

Absolutely. Whether you need a small batch of prototypes to test a concept, a high mix/low volume run, or high-volume production runs, Pinnacle Precision Metal has the capabilities and flexibility to accommodate orders of any size. Our CNC prototyping and high-volume machining processes are optimized for efficiency and precision.

We offer a comprehensive suite of CNC machining services, including CNC Turning, CNC Milling, CNC Routing, and High Volume CNC Machining. Our facility is equipped with advanced machines that enable us to handle a wide range of machining tasks with precision.

Our advanced CNC machining centers, including 5-axis machines, enable us to efficiently produce parts with complex geometries and maintain tight tolerances. Our experienced technical team meticulously plans and executes each project, utilizing cutting-edge software and techniques to ensure precision.

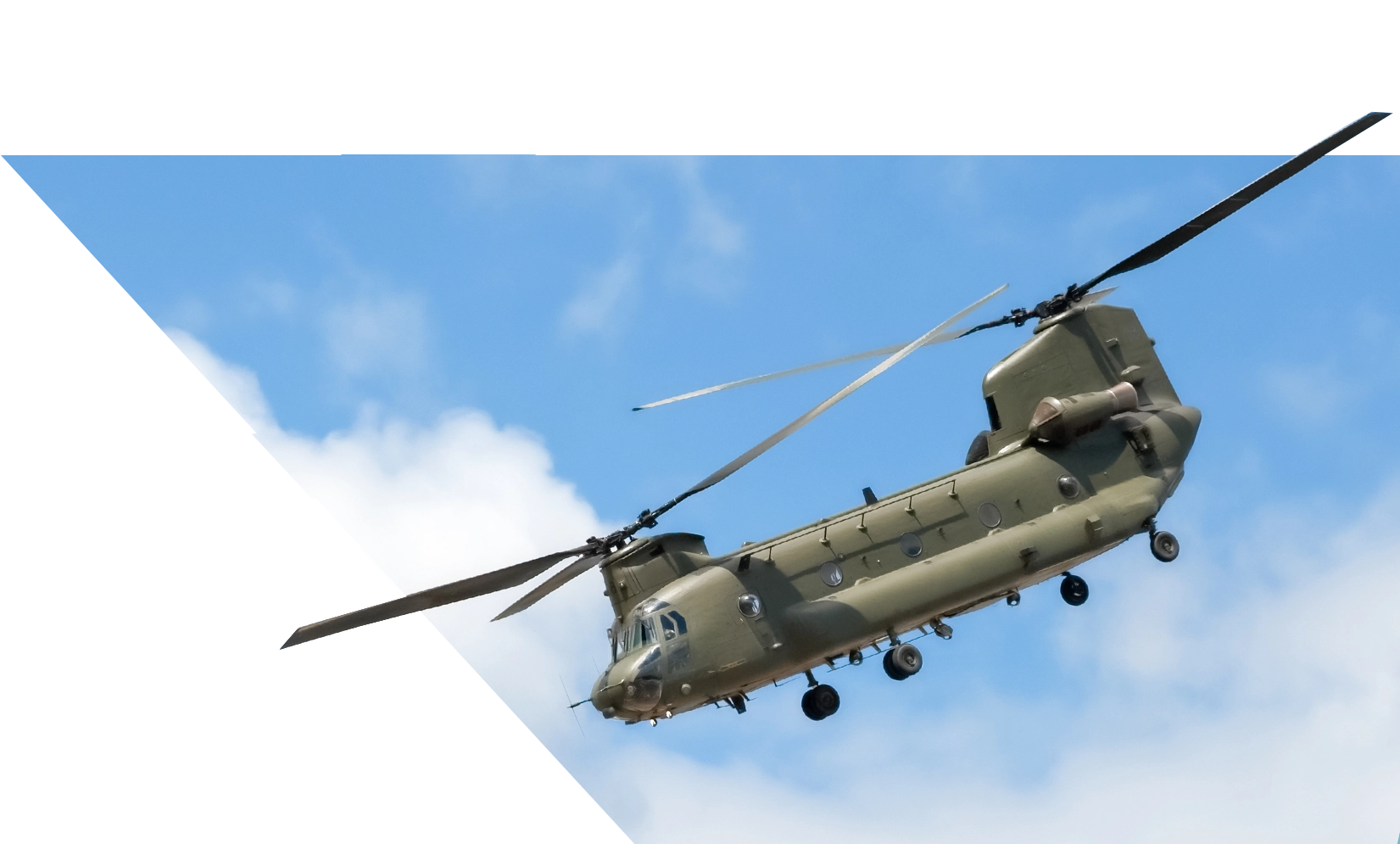

Pinnacle Precision serves a diverse range of industries, with a strong focus on aerospace, medical, defense, technology, and renewable energy sectors. Our comprehensive capabilities, robust quality management system, and material versatility allow us to meet the stringent requirements of these industries.

THE INDUSTRIES WE SERVE

Who relies on Pinnacle Precision for sheet metal fabrication services?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.