We are experts in

CNC Milling

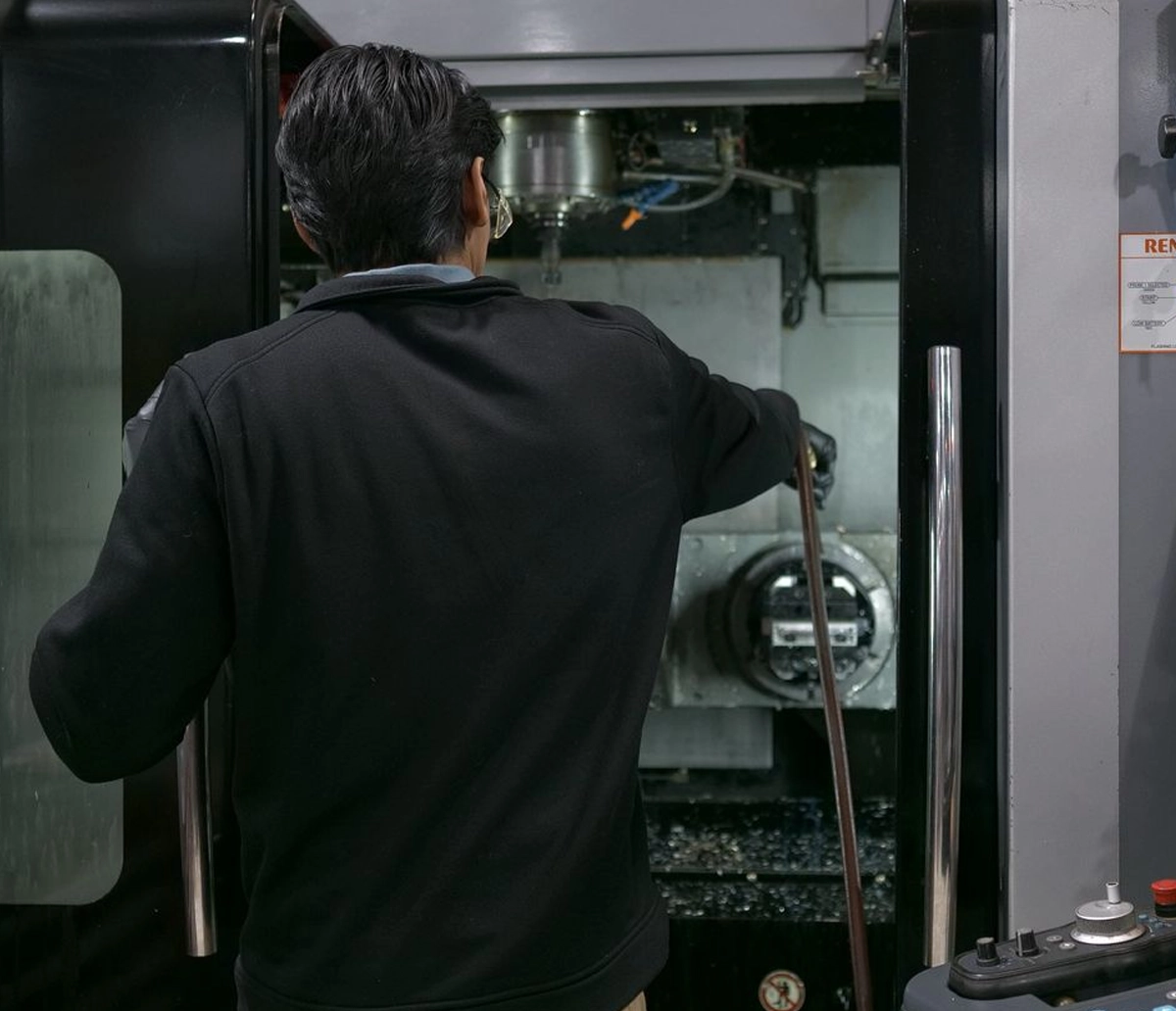

When it comes to custom parts manufactured to precise tolerances, no one does it better than the team at Pinnacle. Boasting a state-of-the-art 73,000-square-foot facility equipped with several CNC-powered multi-axis machines, our CNC machined parts and milling services are renowned for producing high-precision parts with complex geometries and tight tolerances.

With our commitment to care and craftsmanship, our specialized CNC machining service provides customers with greater accuracy and cost savings. Pinnacle’s custom CNC machining processes are tailored for high-precision and high-volume production, covering a wide variety of different operations and machines, from small individual parts to large, heavy-duty gang milling operations. Our specialized team of technicians are experts at working with a wide range of sheet materials, including aluminum, stainless steel, titanium, brass, and tool steel.

With a proven track record across various industries, Pinnacle Precision is a trusted partner for high-quality, high-volume CNC machining advantages.

The tools we use for

Delivering precision CNC machining services

Our investment in multi-axis CNC machines enables us to produce complex parts with unparalleled accuracy and efficiency. There are several CNC-powered multi-axis machines at our state-of-the-art 73,000-square-foot facility, including:

-

(1) 5-axis CNC Machining Center: For intricate parts requiring multi-faceted machining without repositioning

-

(4) 3-axis CNC Machining Centers: For versatile and precise three-dimensional machining

-

(1) CNC Turning Center: For the production of high-precision cylindrical parts.

Leveraging our custom CNC machining services, we achieve incredibly tight tolerances and complex geometries that simply can’t be produced using traditional machining methods. Our proven CNC machining process ensures consistent quality and repeatability, crucial for producing high-precision parts.

Partnered with Pinnacle’s Technical and Production crew, these machines allow us to cut a variety of sheet metal grades to the tightest tolerances using an advanced cutting tool. Our process begins with a detailed CAD file that guides the machining operations, ensuring every part meets exact specifications.

how we deliver

The Pinnacle manufacturing process for precise cutting

Our team meticulously designed the CNC milling process at Pinnacle to ensure the highest standards of precision and quality.

The precise cutting process we use includes several key steps:

Design and CAD Modeling: We create a detailed CAD model of the part. This digital design allows for precise specifications and modifications, enabling rapid prototyping and ensuring the final product meets your project needs.

CAM Programming: Our team converts the CAD model into a CAM (Computer-Aided Manufacturing) program. This step involves defining tool paths, cutting sequences, and other parameters to guide the CNC machine.

Material Selection and Preparation: A suitable material is selected and prepared for the part. Material choice can significantly impact CNC machining service cost and the achievable CNC machining tolerances.

Machine Setup: Pinnacle’s fabrication team sets up the CNC machine with the necessary tools and fixtures, calibrates the machine, and secures the metal to ensure accurate cuts.

Milling Operations: The CNC milling machine performs the programmed operations, which may include drilling, cutting, and finishing. Our precision operations ensure tight CNC machining tolerances.

Quality Control and Inspection: We rigorously inspect every part to ensure it is ready for its intended application. With a focus on quality and reliability, we ensure your part meets the specified tolerances and quality standards.

Post-Processing: Additional post-processing steps may be required to enhance the part’s functionality and appearance, such as deburring, polishing, or coating.

a question we get:

Why choose Pinnacle Precision for CNC milling?

Here at Pinnacle Precision, we’re dedicated to maintaining the highest standards in precision machining, ensuring every part meets exact specifications. Our skilled technicians and engineers bring years of experience and expertise to every project, while our customer-centric approach ensures we deliver solutions tailored to each client’s unique needs.

Our custom CNC machining service and precision CNC milling machines are instrumental in creating a wide range of critical components. We take great care of our machines, maintaining each to ensure precision and repeatability on every project to service various industries.

We also specialize in the manufacturing processes of robust and reliable components and parts that include:

- Enclosures with superior corrosion resistance

- Stainless steel manifolds milled for precise flow control

- Molds and dies manufactured with exceptional accuracy to ensure high-quality production of other parts

Our investment in multi-axis CNC machines enables us to produce complex parts with unparalleled accuracy and efficiency, making us a trusted partner for high-quality, high-volume online CNC machining for clients across various leading industries.

THE INDUSTRIES WE SERVE

Who relies on Pinnacle Precision for sheet metal cutting services?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.