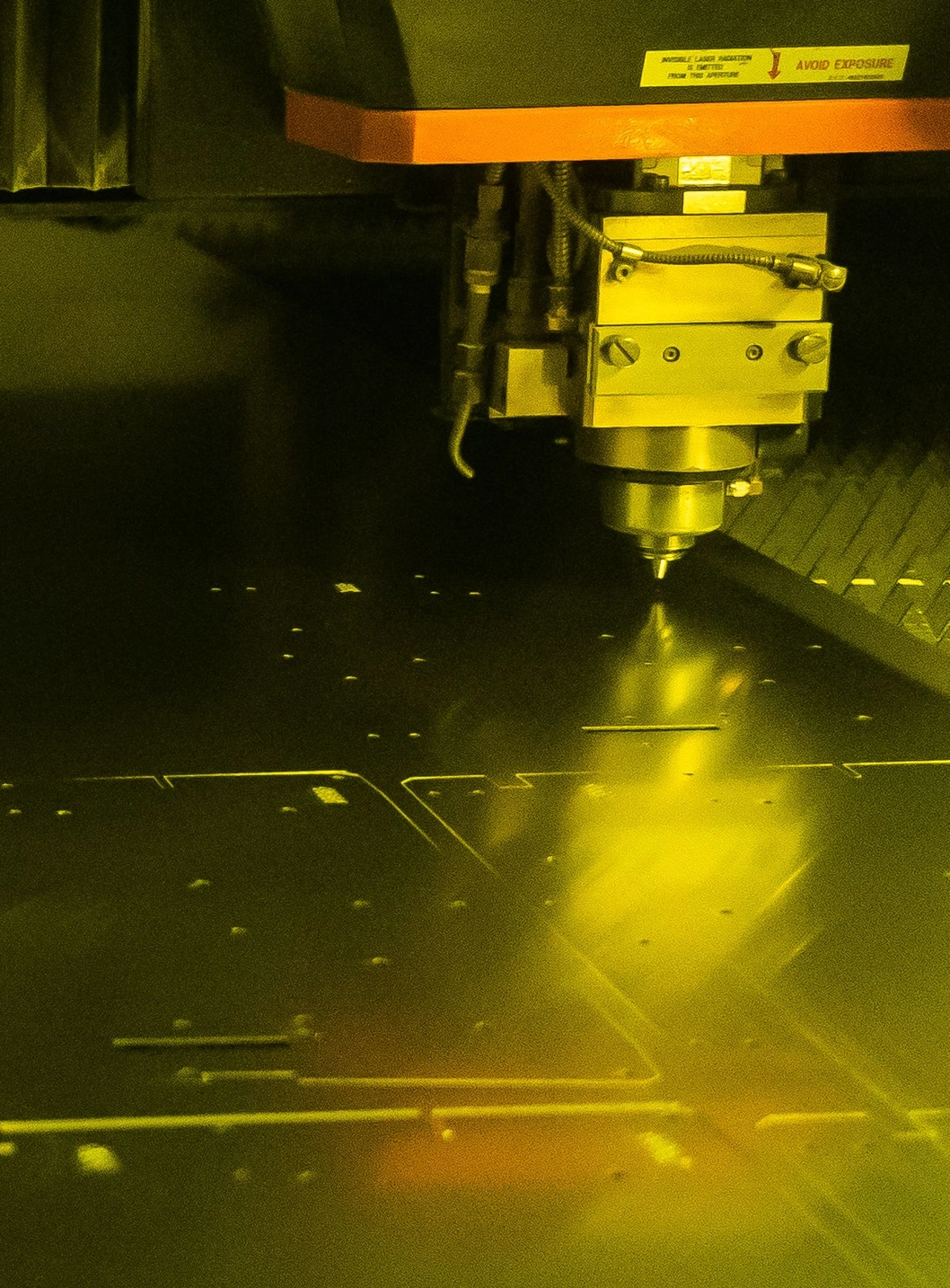

Pinnacle’s production floor boasts a handful of precision CNC laser cutting machines and experienced sheet metal professionals that help set every manufacturing run up for success. Our team is focused on accuracy while cutting to the tightest tolerances and the thinnest gauge sheet metal.

DIM ≤ 8″ [203mm]

8″ [203mm] < DIM ≤ 16″[406mm]

16″[406mm] < DIM ≤ 36″[914mm]

± 0.005″ [0.13mm]

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

± 0.020″ [0.38mm]

± 0.020″ [0.51mm]

± 0.020″ [0.51mm]

± 0.030″ [0.76mm]

±2°

Pinnacle Precision features three flying optics laser-cutting systems with automatic loaders, enabling our crew to run high-speed production days, resulting in highly accurate sheets. Partnered with Pinnacle’s Technical and Production crew, these machines allow us to cut a variety of sheet metal grades to the tightest tolerances.

| Cold Rolled Steel | Aluminum | Stainless Steel |

|---|---|---|

| 24 gauge to ½” | .020 to ⅜” | 24 gauge to ½” |

Customers from leading medical, aerospace, information and communications technology, energy, and entertainment companies come to Pinnacle Precision because they’ve experienced a new level of precision.

Our teams boast decades of experience, working with product sizes ranging from inches to yards and a broad range of sheet metal alloys and finishes.

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our manufacturing experts utilize CNC laser cutting and punch presses for precise sheets that are then delivered to our machining, forming, welding, and finishing departments. From there, we help our customers with assembly, hardware installation, and seal applications before Pinnacle’s quality assurance team carefully looks at the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

Manufacturers use CNC laser and water jet cutting to deliver precisely cut materials to fabricate parts used in essential industries. While both have advantages, laser cutting is superior when working with sheet metal and metal alloys.

Laser cutting is superior in many situations due to its speed, precision, efficiency, and versatility. Using lasers enables a high degree of repeatable and efficient

accuracy during production runs, especially when delivering parts designed to be weather and corrosion-resistant, durable, and flexible.

Water jet cutting is preferable for thicker materials, like stone, glass, or plastics. The process does not produce heat, reducing material warping or distorting risks. Yet, water jet cutting is a slow process that’s not ideal for deadline-driven projects.

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.