We are experts in

Welding Sheet Metal

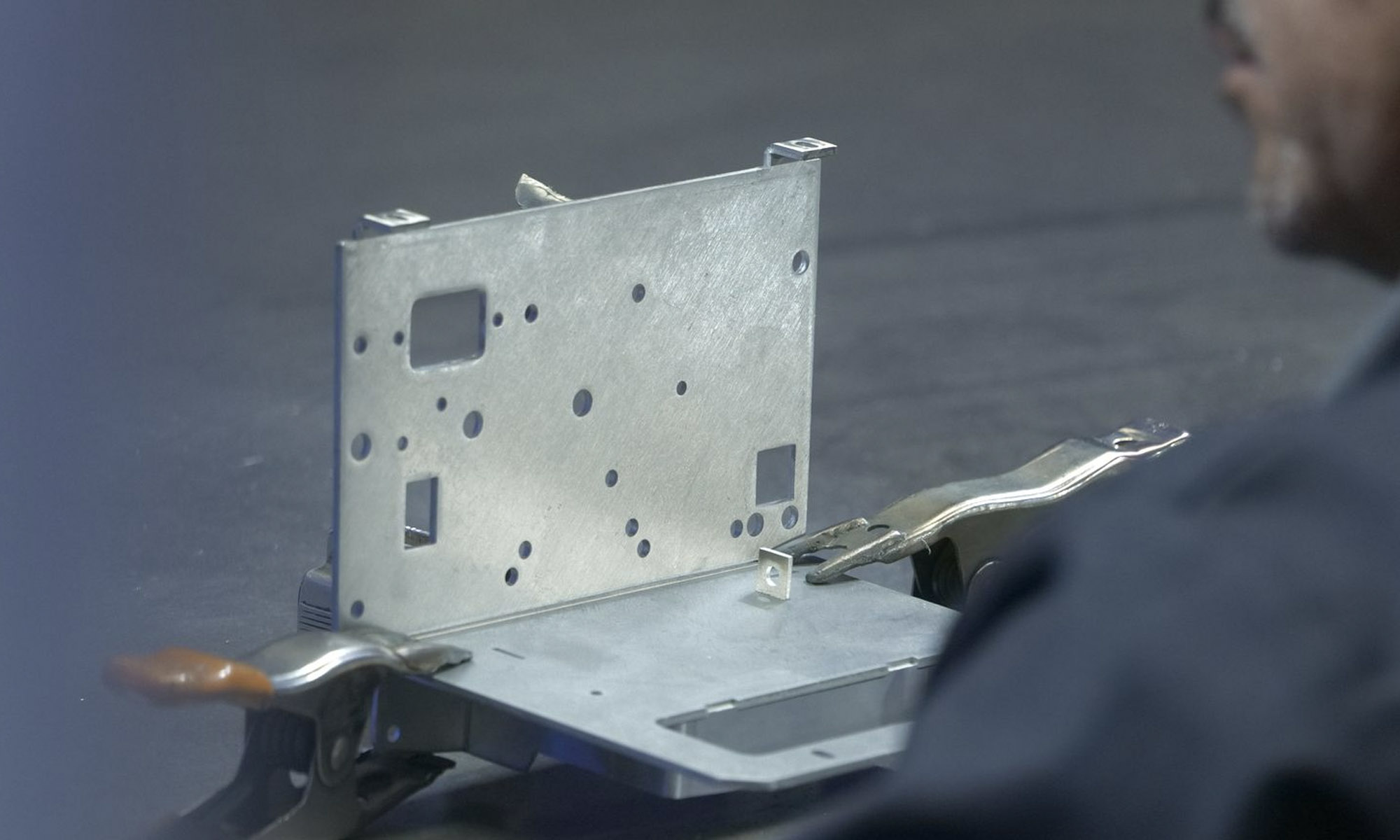

Our team of certified and experienced welders brings random parts together to create assemblies used in essential components. Pinnacle’s production floor boasts six Arc welding machines, a pair of MIG machines, and six spot welding machines. Our team works on sheet metal, aluminum, and stainless steel, welding from 20 gauge up.

The tools we use for

Precision welding

Welding parts together that our clients use to support our most important industries is an art and science. So, we make sure that our welders have the best tools possible, including 8 TIG welder stations, one MIG welder, and five spot welding machines. Our expert crew has the skill to weld at the smallest gauges for Class A parts with speed and accuracy.

-

(1) TIG welder, 250 amp

-

(7) TIG welder, 275 amp

-

(1) MIG welder, 250 amp

-

(5) Multi-tip welder, kVA 100

how we deliver

The Pinnacle process

Customers from leading medical, aerospace, information and communications technology, energy, and entertainment companies come to Pinnacle Precision because they’ve experienced a new level of precision.

Our teams boast decades of experience, working with product sizes ranging from inches to yards and a broad range of sheet metal alloys and finishes.

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our manufacturing experts utilize CNC laser cutting and punch presses for precise sheets that are then delivered to our machining, forming, welding, and finishing departments. From there, we help our customers with assembly, hardware installation, and seal applications before Pinnacle’s quality assurance team carefully looks at the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

a question we get:

What steps do you take to avoid sheet warping during welding?

Our expert welders take great care to ensure the integrity of every part they work on, understanding that any warping compromises the success of our customer’s products.

Pinnacle Precision relies on all experienced human welders — no robots here — who work methodically and precisely through every project.

We start by mapping out the order of welds to distribute heat evenly across the piece, utilize tack welding as needed, and carefully work on each piece with lower heat inputs where necessary.

The welders in our Production crew boast decades of experience working on large parts used by our energy customers and smaller detail parts for our medical customers.

THE INDUSTRIES WE SERVE

Who relies on Pinnacle Precision for welding and fabrication services?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.