Raw materials become perfect parts, components, and assemblies after expert manufacturers deliver precision metal fabrication services, including cutting, punching, forming, welding, and grinding. Pinnacle leverages the power and accuracy of CNC-powered machines across our 73,000-square-foot production floor while answering the call from industry-leading medical, aerospace, defense, communications, technology & information, entertainment, and renewable energy companies.

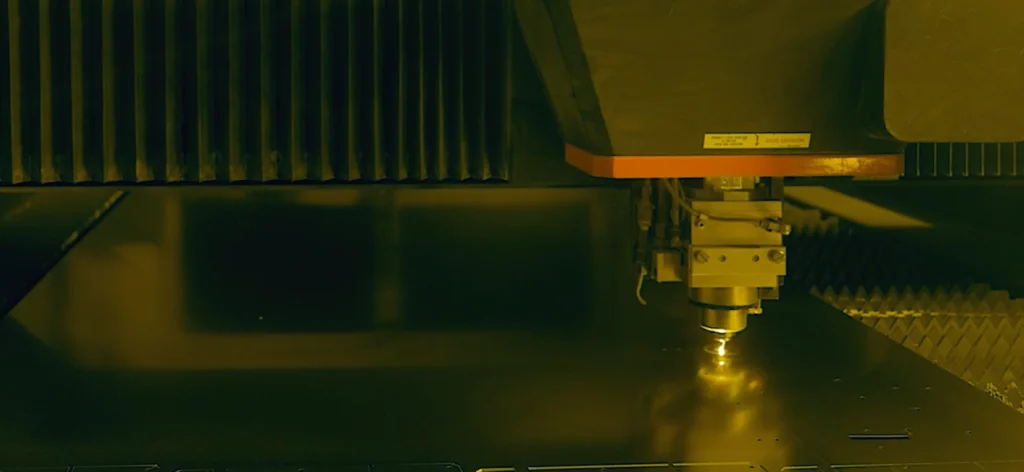

CNC laser-cutting machines enable Pinnacle’s production team to cut and shear parts and components with accuracy and repeatability.

Pinnacle’s Technical and Production teams combine to turn raw materials into precision parts and components via CNC-powered machines.

CNC forming presses deliver accurate and durable parts up to 10 feet in length from a large selection of dies and tools.

Spot, tack, TIG, and MIG experts work with a range of materials and gauges for fast and accurate welds that are crucial for precision components.

Wet and dry line graining, deburring, grinding, and sanding remove any imperfections created during manufacturing to prep parts for finishing.

Pinnacle’s Technical, Production, and Quality Assurance teams leverage decades of experience and expertise to deliver parts, components, and assemblies to industry-leading medical, aerospace, defense, communications, technology & information, entertainment, and renewable energy companies.

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our crews work with product sizes ranging from inches to yards, a broad range of sheet metal alloys and finishes, and runs from prototype to production.

The 73,000-square-foot production floor at Pinnacle features CNC-powered laser cutting and punching machines, dozens of press brakes (with a 50- to 125-ton capability), and dedicated weld and grind spaces.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.