We are experts in

FinishingMetal Parts

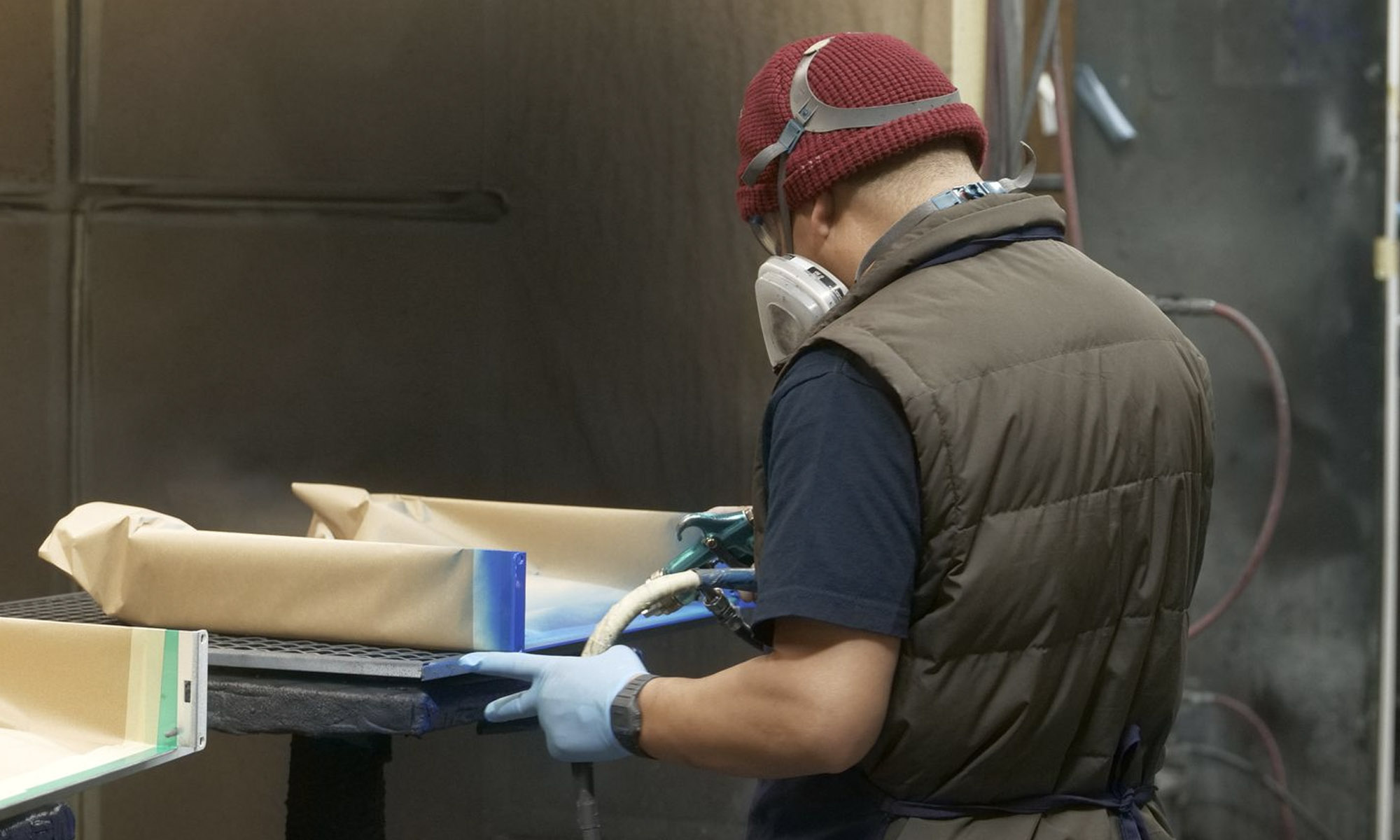

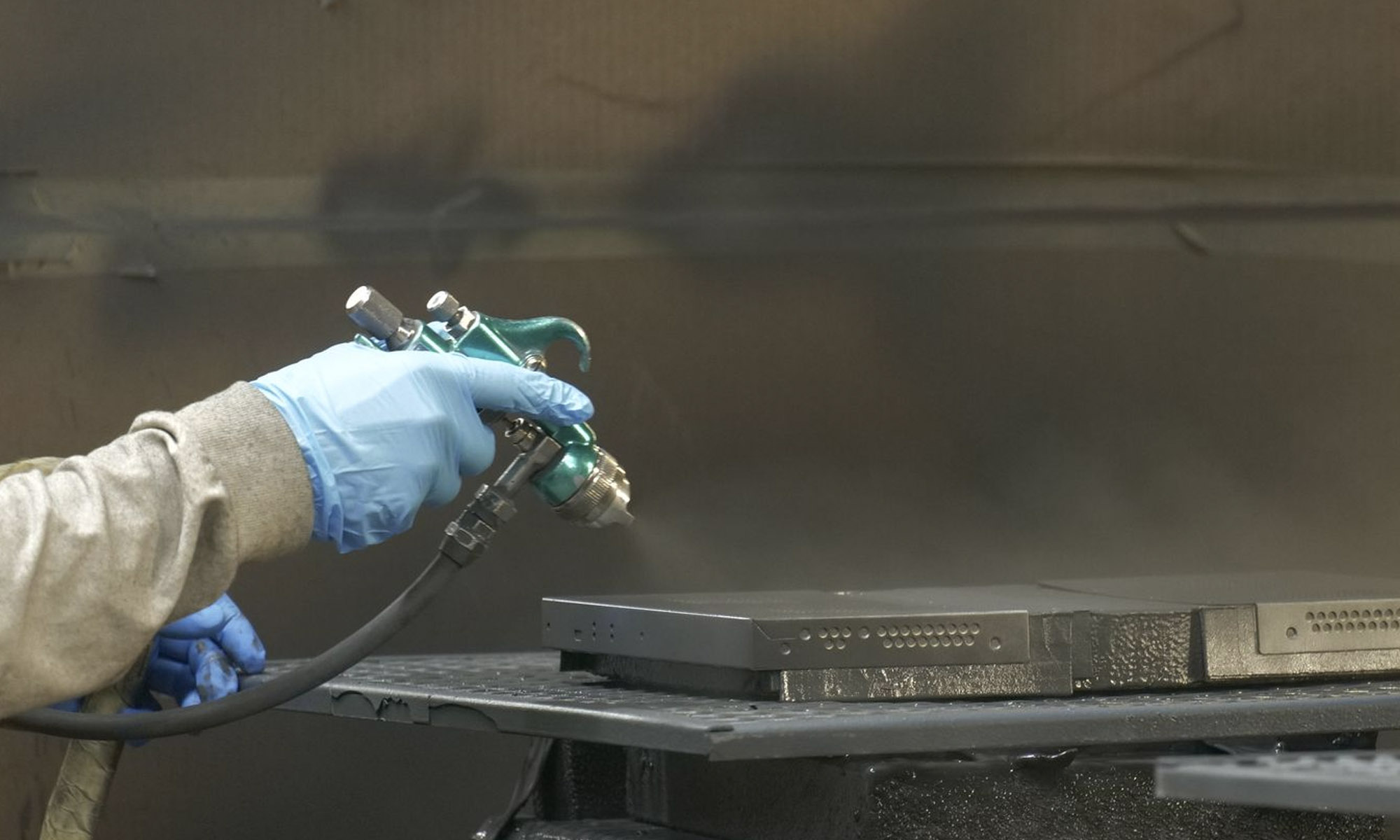

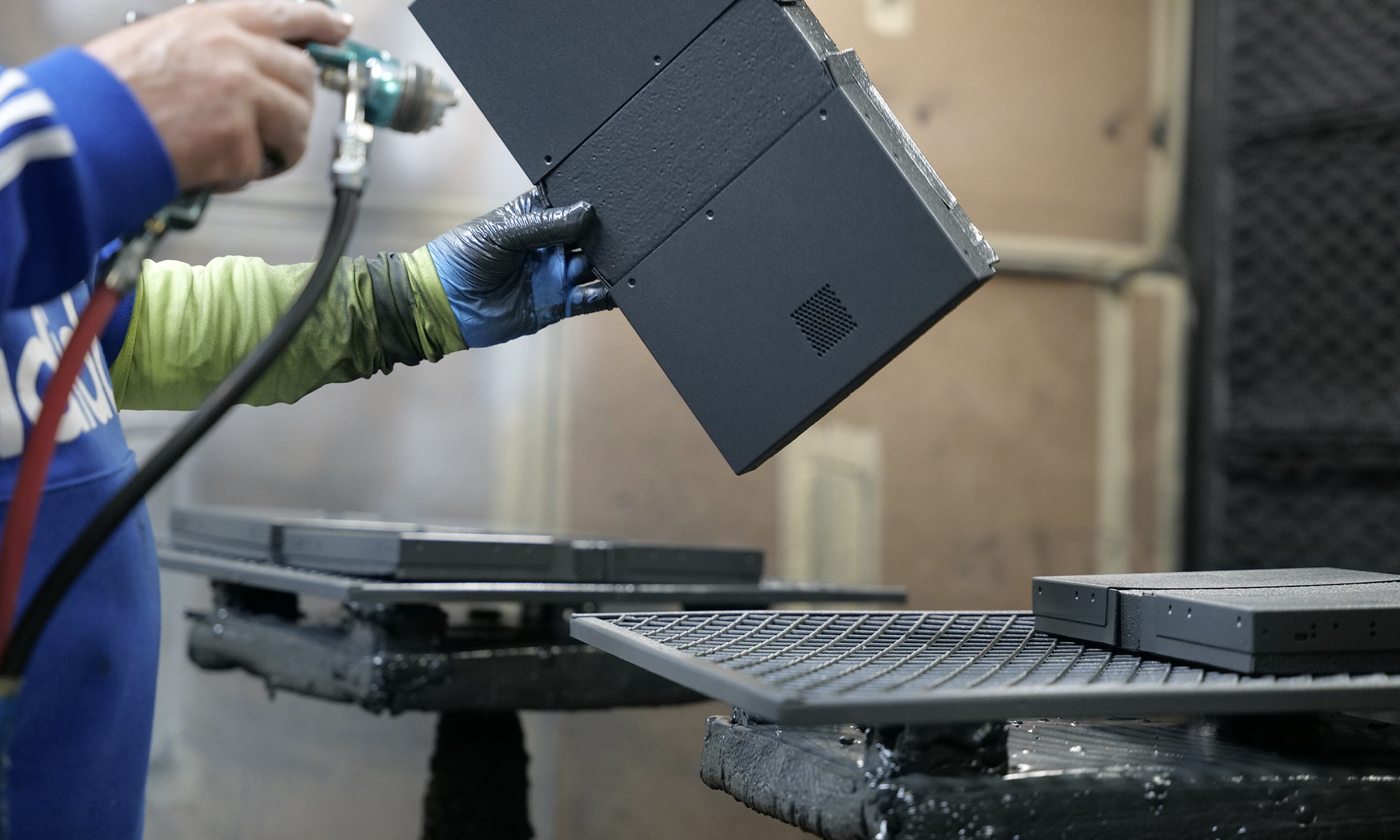

Making metal parts pretty and protected from the elements is job number one for Pinnacle’s commercial paint, powder coating, and silkscreening crews. The team uses industry-leading materials to enhance the strength, durability, and appearance of every painted part produced here, including paint and powder specially designed for use in medical, aerospace & defense, and harsh environments.

General Dimensional Tolerances

Dimension Range

DIM ≤ 8″ [203mm]

8″ [203mm] < DIM ≤ 16″[406mm]

16″[406mm] < DIM ≤ 36″[914mm]

Edge to Edge, Hole to Hole, Edge to Hole on Flat

± 0.005″ [0.13mm]

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

Edge to Hole to Bend

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

± 0.020″ [0.38mm]

Bend to Bend

± 0.020″ [0.51mm]

± 0.020″ [0.51mm]

± 0.030″ [0.76mm]

Angular Tolerance

±2°

The tools we use for

Expert finishing

Pinnacle Precision’s Finishing department is one of Southern California’s best sheet metal finishing companies. We can handle epoxy, polyurethanes, and water-based coatings to deliver smooth and textured finishes, powder coatings, and silkscreening projects.

-

(2) 8’ X 8’ standard liquid spray booths

-

(1) 18’ X 15’ standard liquid spray booths

-

(2) Conveyorized powder booths with automatic spray guns

-

(1) Conveyorized powder coat booth oven

-

(1) Light integrator

-

(1) Vacuum Frame (SPWM 48” x 60”)

-

(1) Batch oven

-

(20) Silkscreen workstations

THE MATERIALS WE USE

Paint Thickness Range

| Paint Process | Thickness Range |

|---|---|

| Wet Paint | .0015-.003" |

| Powder Coating | .003-.005" |

how we deliver

The Pinnacle process

Customers from leading medical, aerospace, information and communications technology, energy, and entertainment companies come to Pinnacle Precision because they’ve experienced a new level of precision.

Our teams boast decades of experience, working with product sizes ranging from inches to yards and a broad range of sheet metal alloys and finishes.

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our manufacturing experts utilize CNC laser cutting and punch presses for precise sheets that are then delivered to our machining, forming, welding, and finishing departments. From there, we help our customers with assembly, hardware installation, and seal applications before Pinnacle’s quality assurance team carefully looks at the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

a question we get:

What are the benefits of powder coating sheet metal?

The Finishing crew at Pinnacle Precision boasts expertise in painting and powder coating sheet metal parts used by our customers in the medical, aerospace, communications, and energy industries. While painting and powder coating makes sense when finishing sheet metal, powder coating has several benefits.

These benefits alone are helpful for our clients who are building components situated in harsh environments.

Powder coating also is a more efficient process in the finishing stage and is easier to maintain when out in the field. Plus, powder coating adds electrical insulation and chemical resistance to every part.

Powder coating sheet metal gives parts a strong finish resistant to wear, chipping, and scratching while adding a protective layer that produces strong corrosion resistance.

THE INDUSTRIES WE SERVE

Who relies on us for precision metal finishing?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.