When you’re developing precision components for OEM applications, the choice of a CNC machining manufacturer isn’t just about cutting metal — it’s about long-term project success beyond the part drawing. From ensuring tight tolerances to delivering on time and scaling with your production needs, your machining partner plays a critical role in your product’s lifecycle. At Pinnacle Precision, we take this partnership extremely seriously, and we understand that choosing to trust us within your supply chain does not come lightly or without proper due diligence.

With tens of thousands of spindles across America, navigating the supply chain for potential new suppliers can be daunting. From onboarding, manufacturing readiness reviews (MRR), and establishing streamlined communication from production teams through quality engineers, there is plenty to get bogged down on. With every unsuccessful onboard, failed MRR, or program manager who simply doesn’t prioritize your work, these situations create delays that could be detrimental to the launch or scaled growth of your product, but more importantly, the confidence your customers have that you can deliver on a consistent basis.

For engineers, procurement teams, and project managers, aligning with an organization to fulfill your requirements can mean the difference between a smooth product launch and costly setbacks. This guide will walk you through the key criteria to evaluate when selecting a machining partner, including the importance of robust manufacturing processes, and more importantly, explain why companies across aerospace, medical, and industrial sectors trust Pinnacle Precision to deliver mission-critical components, to their exact specifications, delivered on time, every time.

What to Look for in an OEM CNC Machining Partner

ICYMI: What is CNC Machining?

CNC (Computer Numerical Controlled) machining is a manufacturing process controlled by pre-programmed computer software to generate G-Code, otherwise known as the machine’s language.

Before machining begins, computer-aided design (CAD) software is used to create detailed digital models and set precise dimensions for the parts to be produced. Utilizing various modeling and tool path simulation software systems to create the most optimal cutting path creates an in-tolerance part and ensures the longevity of the machine tools for future parts and products.

CNC programming refers to the process of creating and editing the code that directs the machine’s movements and operations. The origins of CNC machining can be traced back to numerical control, where early systems used computational methods and Cartesian coordinates to automate machine tool movements, eventually evolving into modern computer numerical control machining.

Most commonly, CNC operations can be found in high-volume production equipment like lathes, mills, and routers, which can achieve extremely repeatable results, while also replacing manually controlled machine tools that can be costly in terms of production cycle times. In manual control, machinists operate equipment directly, making live adjustments and inputs, whereas automated CNC processes rely on software and programming for precision and efficiency.

CNC machining is essential in metal, plastic, and composite production due to its automation capabilities, enabling the production of complex shapes and components with exact specifications and consistent repeatability.

This process is widely used in various critical industries, including aerospace, automotive, and medical devices, for its ability to deliver high-quality, custom parts with extremely tight tolerances.

Pinnacle Precision’s Core Capabilities

The CNC machining process can be different from one supplier to the next, which is what separates the “great to work with shops” from the supplier that only causes you more problems than it solves. At Pinnacle, we consider how we approach precision CNC machining, including the use of CNC lathes, to be at the core of what makes us different from other suppliers. There is a comprehensive balance between choosing the right equipment for specific material types, complexity, and application requirements for both function and durability.

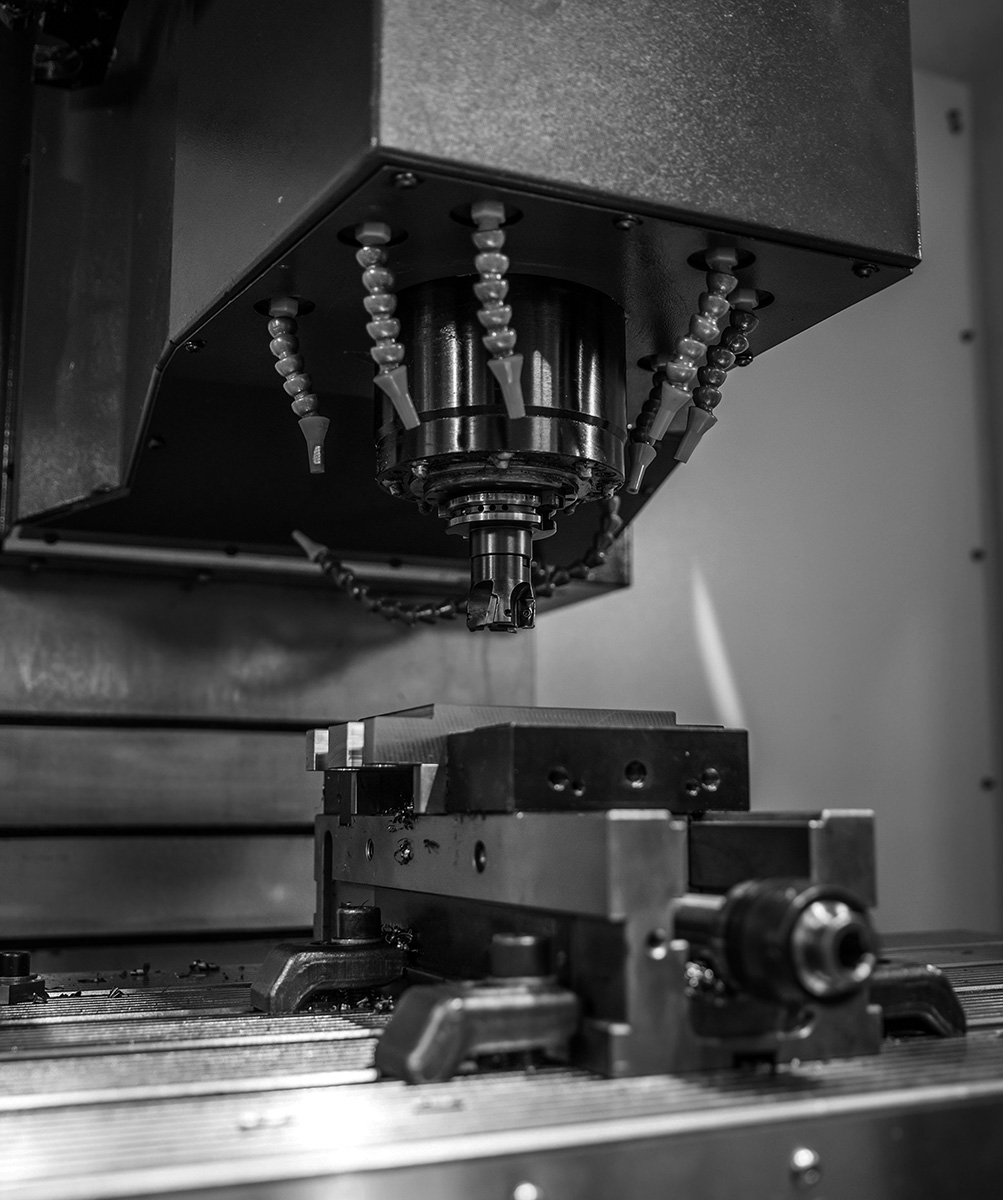

3 Axis Milling: Where the workpiece is typically secured on a flatbed, while the cutting tool moves along three linear axes: X (left to right), Y (front to back), and Z (up and down). This setup allows the machine to cut and shape a workpiece from multiple directions, but only from one side at a time. This process can be optimized by adding 4th-axis rotary tables, which allow for additional indexing.

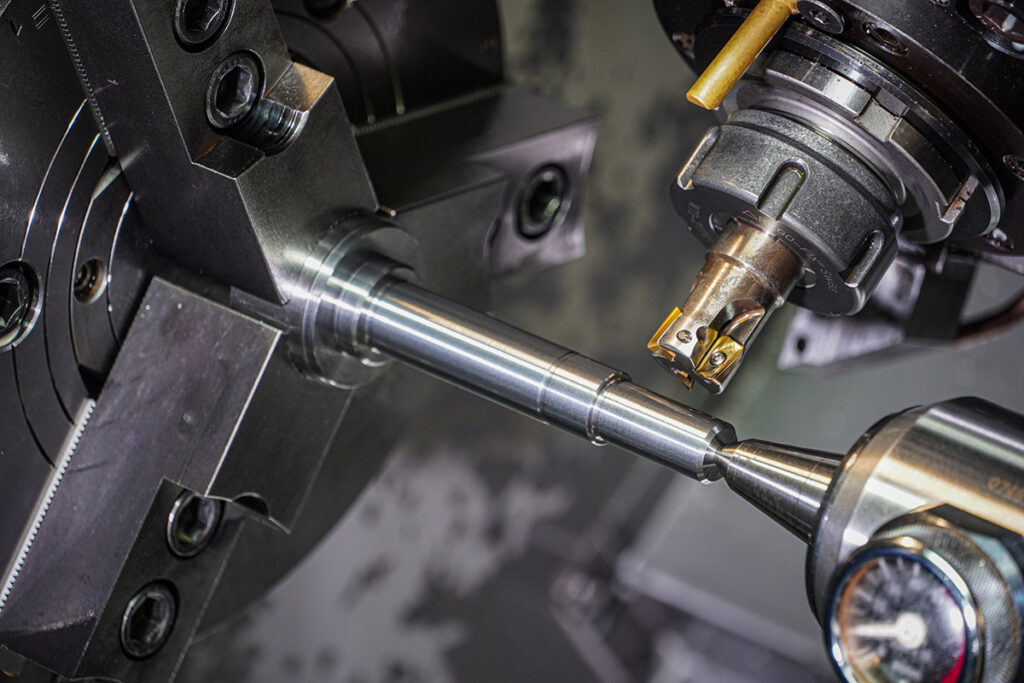

Turning: Is the standard practice used to create round or cylindrical parts by rotating a workpiece while a stationary cutting tool removes material. Unlike standard vertical milling, where the part is stationary and the machine does all of the moving, CNC turning, or lathe machining is the process of moving the part instead. This process can be optimized through the use of live tooling options and multiple spindle configurations.

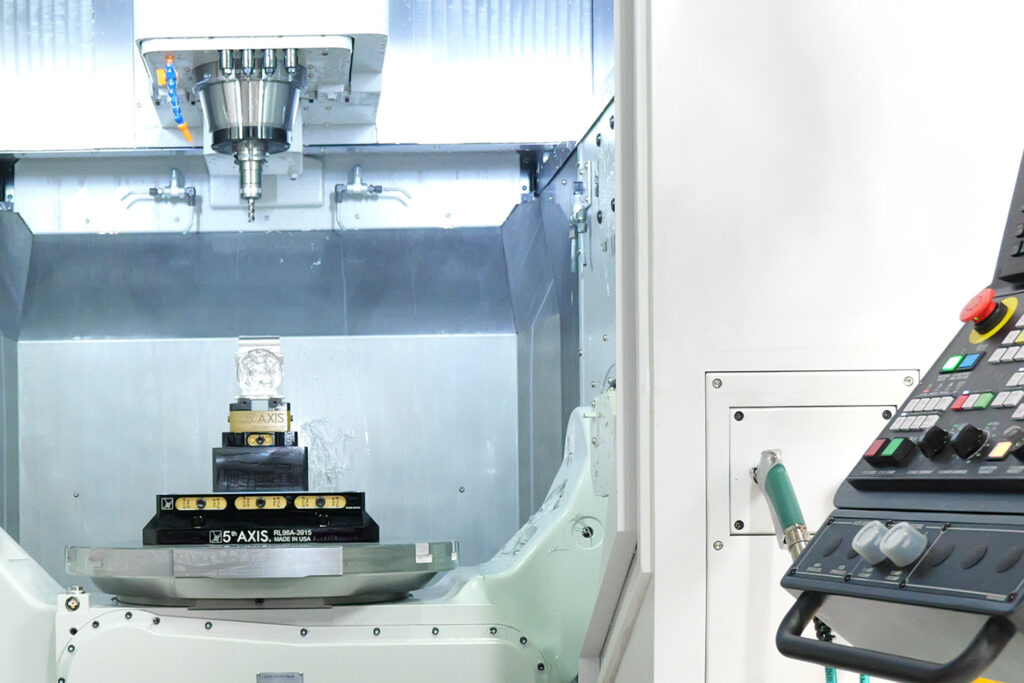

Multi-Axis: 5-axis CNC milling is an advanced machining process where cutting tools move across five different axes simultaneously. This includes X, Y, and Z (linear), plus A and B (rotational), allowing for the creation of highly complex, contoured parts in a single setup. Unlike traditional 3-axis milling, which can only cut in three directions, 5-axis machining enables access to all sides of a part without manual repositioning, significantly improving precision, surface finish, and efficiency.

Our Material Expertise

We have extensive experience machining a wide range of materials, including various metal alloys such as aluminum, steel, and stainless, a diverse mix of plastics, as well as high-performance composites. Our expertise includes working with durable materials and starting from a solid block to create precise components. We also process electrically conductive metals like copper for specialized applications. Below is a list of standard materials we process, but our experience goes well beyond what is most commonly used, so don’t hesitate to request more information if your material isn’t mentioned:

Metal Materials

We have extensive experience machining a wide range of materials, including various metal alloys such as aluminum, steel, and stainless, a diverse mix of plastics, as well as high-performance composites. Our expertise includes working with durable materials and starting from a solid block to create precise components. We also process electrically conductive metals like copper for specialized applications. Below is a list of standard materials we process, but our experience goes well beyond what is most commonly used, so don’t hesitate to request more information if your material isn’t mentioned:

Aluminum

Here are some common aluminum alloys used in CNC machining, each offering unique mechanical properties and corrosion resistance:

- 1000 Series (1100) – Commercially pure aluminum, used in electrical and chemical applications

- 2000 series (2024) – High strength, typically used in aircraft structural components

- 5000 series (5052) – Corrosion resistance, used in maritime applications as well as chemical and fuel tanks

- 6000 series (6061) – Extremely versatile, used in structural components for aerospace and automotive

- 7000 series (7075) – Tough stuff but still lightweight, great for military and high-performance applications

Steel

- Carbon Steel (1018, 1045, A36, AR500) – Affordable and great machinability for gears, shafts, fixtures, and structural components across nearly every industry

- Alloy Steel (4130, 4140, 4340) – High strength and heat treatable, great for machining tooling, aerospace, and automotive applications

- Stainless Steel (303, 304, 316, 17-4) – Great corrosion resistance, often used in medical devices, food-grade applications, and aerospace components.

- Tool Steel (D2, A2, O1) – Extremely hardened steel and wear-resistant, great for dies, molds, and cutting tools.

Plastic Materials

- ABS (Acrylonitrile Butadiene Styrene) – Great for prototyping to test functionality

- Delrin (POM – Polyoxymethylene) – Great for gears, bushings, and bearings due to its low friction properties

- Nylon (Polyamide) – Excellent for spacers, insulators, and fasteners, with low moisture absorption for dimensional stability

- PTFE (Teflon) – Optimal for seals, gaskets, and electrical insulation, offering low friction and outstanding chemical resistance

- PVC (Polyvinyl Chloride) – Versatile material known for its chemical resistance and wide range of applications

Composite Materials

- Carbon Fiber – The pinnacle of performance among composite materials, extremely durable while also being lightweight, commonly used in aerospace and automotive high-performance applications.

- Fiberglass – A widely used material for electrical housings and marine components, lightweight and impact-resistant

We Don’t Get Intimidated by Part Complexity

At Pinnacle, our CNC machining services go well beyond nuts and bolts, and we look forward to applications that include complex geometries. We have extensive experience handling complex parts and supporting demanding applications that require specialized solutions. From CNC turning to CNC milling or a combination of both capabilities, we have the confidence that using the correct CNC machining process with our cutting-edge equipment will produce precise parts while meeting the tighter tolerances required for advanced projects. Post-processing is also a critical step to ensure the desired surface quality and finish, especially for complex parts.

Quality Comes First

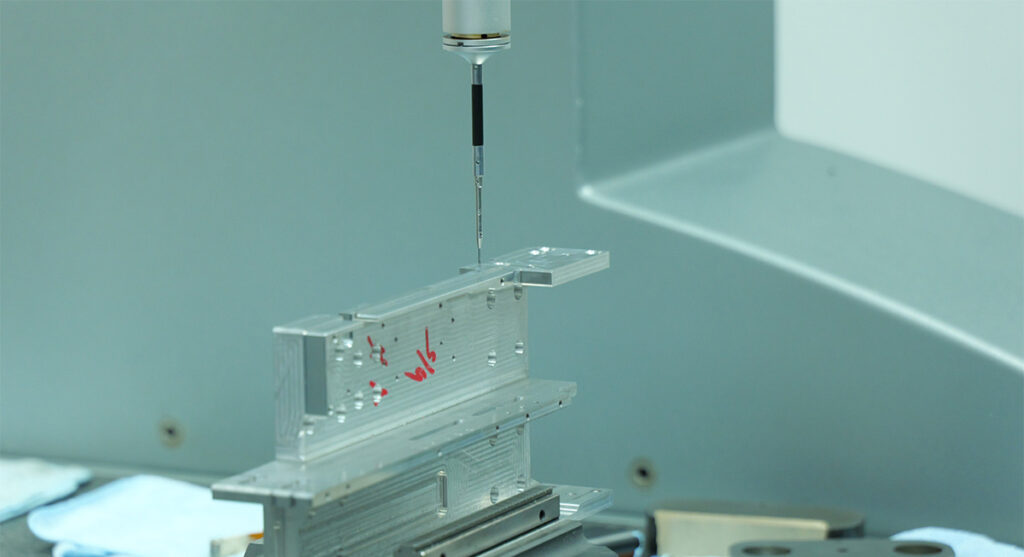

Pinnacle is committed to going beyond industry standards and consistently exceeding customer expectations by delivering mission-critical parts precisely when they’re needed. Guided by the Quality Assurance motto, “Quality people make quality parts,” every team member is empowered to take ownership of quality within their role.

At Pinnacle, we also provide ongoing training that reinforces this culture, ensuring that quality isn’t just a department, it’s a shared responsibility. Pinnacle’s dedicated Quality Assurance team develops and enforces rigorous procedures to meet and maintain compliance with ITAR, ISO 9001:2015, AS9100D, and RoHS certifications. These advanced quality control systems are implemented throughout our processes to ensure consistent product quality during high-volume manufacturing and to prevent inconsistencies across large production runs.

Although all manufacturers that share these qualifications are required to uphold the standards outlined within them, we consider this to be extremely important when it comes to custom CNC machining or OEM parts machining, and we ensure the importance runs throughout the entire company.

We Grow with You, and Keep Up with Your Schedule

In most cases, shops are either focused on prototyping a high mix, low volume program, or they want nothing to do with prototyping and only want to get involved once you’ve proven your design and need to produce hundreds to thousands of units. At Pinnacle, we see partnerships differently, where having direct involvement with DFM (Design for Manufacturability) with your supplier makes iterations and changes more advantageous for both parties and ultimately leads to a smooth ramp-up into production.

When dealing with any supplier, lead time and on-time delivery are equally as important, if not more critical, than the price of the part itself. CNC machined parts are great, but only if they show up on time; otherwise, we are just performing metal cutting exercises, which ultimately benefit no one. Production quality creates cost efficiency, but it also enhances efficiency when moving into full-scale production, which is ultimately how we get out of the prototype stage. All of this still comes down to a core pillar of our operation, which is delivering parts on time when you need them most.

With our CNC machining capabilities, ability to process different materials, comfort with complex designs, and other processes, Pinnacle is dedicated to seeing your prototype parts transition to production parts. We can be as flexible as you need us to be, slow down during critical design reviews, and ramp up in order to meet the deadlines.

Communication Makes the Difference

Clear, proactive communication is essential in CNC machining projects, where timelines and collaboration directly impact the final outcome. At Pinnacle Precision, communication isn’t an afterthought, it’s built into every stage of our process both internally and externally. From the initial quote to final delivery, customers can expect transparency, fast response times, and consistent updates that keep projects on track and eliminate surprises.

Equally important is the ability to engage early and offer Design for Manufacturability (DFM) feedback. Our team works closely with engineers and project managers to review part designs and identify opportunities to improve cost efficiency, reduce complexity, and ensure reliable production. Sharing a CAD file during these design reviews is crucial, as it allows for effective collaboration and thorough manufacturability analysis using our computer-aided design tools. This upfront collaboration helps prevent issues later in the process, saving time and resources for everyone involved.

Beyond DFM, Pinnacle offers hands-on engineering support to ensure parts are optimized for both performance and producibility. Whether it’s recommending alternate materials, refining tolerances, or addressing potential production challenges, the team partners with our clients to align technical goals with manufacturing realities, making Pinnacle not just a vendor but a true CNC machining partner.

Your Best Value Option

At Pinnacle, we believe value goes far beyond the quote. While some vendors may offer lower upfront pricing, those savings often quickly disappear due to part failures, missed deadlines, or design revisions brought up after they receive the PO. Pinnacle takes an ownership approach, considering everything from consistent quality and on-time delivery to reducing rework and refining communication. This ensures that OEMs get parts that perform as expected, arrive on schedule, and support smooth product launches.

By investing in quality processes, experienced staff, and advanced equipment, Pinnacle helps customers avoid the hidden costs that often come with low-cost suppliers. Our proactive engineering approach supports and focuses on manufacturability to reduce the risk of design issues, and our responsive service minimizes delays. The result is a CNC machining partner that delivers lasting value, not just seductive pricing.

Why Pinnacle Precision is a Trusted CNC Partner

Located in the heart of precision CNC machining in California, Pinnacle’s collection of multi-axis CNC machines, expert programmers, and versatile operators produces machined components with intricate designs to the tightest tolerances. Our machine shop delivers dependable and accurate products for prototype, high-mix/low-volume, and high-volume production, including custom CNC parts for various industries.

Extensive Machining Capabilities: From tight tolerance milling and turning to multi-axis CNC, Pinnacle handles the most challenging designs.

Material Versatility: Proficient in aluminum, stainless steel, titanium, engineered plastics, and more, with experience producing parts and materials for medical industries and handling materials with specific electrical conductivity requirements.

Certifications & QA: ISO-certified with rigorous quality systems and in-house inspection capabilities.

Reliable Delivery: Fast, consistent lead times and a strong track record of on-time shipments.

Collaborative Support: Responsive engineering and account teams focused on long-term project success, equipped with the latest factory tools.

Whether you’re launching a new product or scaling production, Pinnacle offers the precision, responsiveness, and partnership mindset you need and deserve.