This article explores the advantages of full-service metal assembly over traditional methods, highlighting its benefits and integration strategies for your projects.

Whether you’re an engineer, project manager, manufacturer, or procurement professional, you’re no doubt always searching for ways to optimize the efficiency and cost-effectiveness of your projects without compromising on precision.

Providing streamlined processes, enhanced precision and quality control, and reduced complexity of the manufacturing workflow, it’s easy to see why full-service metal part assembly and electromechanical assembly have become popular solutions.

Delivering the perfect fit and functionality of your sheet metal components, these turn-key solutions streamline the entire production process, reducing lead times and costs by consolidating various fabrication, finishing, and assembly steps under one roof. With full-service metal part assembly, projects achieve enhanced precision and benefit from a more streamlined and cost-efficient manufacturing lifecycle.

Pinnacle Precision is recognized as a premier provider of full-service metal part assembly solutions, catering to a wide array of industries. With decades of experience, the company excels in delivering precision-crafted metal components and comprehensive assembly services that consistently meet and surpass stringent quality standards.

This article breaks down the key aspects that set full-service metal assembly apart from traditional assembly methods, the benefits this precision manufacturing service can deliver, and strategies for integrating it into your projects.

What is Full-Service Metal Part Assembly?

Full-service metal assembly represents a comprehensive approach to manufacturing that goes beyond traditional assembly methods. Unlike conventional practices, full-service metal assembly, which may involve the use of filler metal, incorporates a more integrated and refined process.

Full-service metal assembly involves the meticulous coordination of various sheet metal parts, ensuring a seamless fit and enhanced precision in the assembly process. This method eliminates reliance on external fasteners, optimizing structural integrity and reducing the risk of component misalignment.

The process starts with fabricating metal components according to exact customer specifications. These components may include metal sheets, plates, brackets, panels, enclosures, or other parts required for the final product.

In addition to fabricating individual parts, a full-service manufacturer like Pinnacle possesses the expertise and equipment necessary to assemble these components into a final product. This may involve welding, fastening, riveting, soldering, or any other assembly techniques relevant to the project. The service can also be fully tailored to meet the customer’s specific needs, allowing for customization of the assembly process to accommodate unique project requirements.

When you work with a total assembly sheet metal manufacturer like Pinnacle, you get peace of mind knowing that your components will align flawlessly while adhering to strict tolerances and quality standards.

What is Electromechanical Assembly?

Electromechanical assembly is the process where wire harnesses, cable assemblies, subassemblies, switches, power boxes, or circuitry are assembled with fabricated metal components to create a component ready for use.

Each component is custom-built for maximum reliability, durability, and accuracy since most are used in demanding, highly sensitive applications, including aerospace, defense, medical, and energy.

Many OEMs today are looking for ways to boost efficiency and increase cost savings by looking for a manufacturing partner that can handle all aspects of electromechanical assembly.

Yet, those are just two of the many benefits of relying on one shop to handle an electromechanical assembly project. Faster development and product refinement are additional benefits, as are resource optimization and improved quality control.

Finding a partner with a history of accurate fabrication, attention to detail, strong project management, and rigorous quality assurance protocols is essential. Plus, that partner must adhere to the highest accreditation standards, including ISO:9001:2015, AS9100D for aerospace work, and ITAR for defense projects.

Electromechanically assembled components include assemblies for power supplies, transformers, cockpits, medical devices, and heavy equipment.

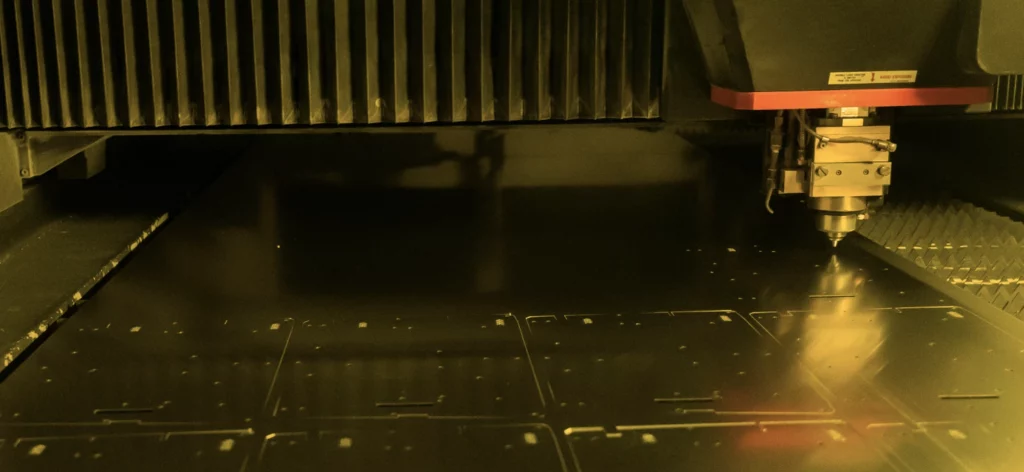

What is the Role of CNC Machining in Full-Service and Electromechanical Metal Assembly?

CNC machining is essential when it comes to full-service and electromechanical assembly projects because precision is vital when integrating fabricated metal with wire harnesses, switches, and more.

CNC machining offers consistent and accurate metal parts to the assembly line, saving time during the integration process, reducing the amount of rework needed, and ensuring a durable component.

Plus, CNC machining is a cost-effective solution for custom-designed metal parts that are necessary for most full-service and electromechanical assemblies.

The Benefits of Full-Service and Electromechanical Metal Assembly

The main benefits of full-service and electromechanical metal assembly lie in the precision and efficiency achieved through the cohesive integration of metal assemblies. This approach ensures a streamlined manufacturing process, optimizing structural integrity and overall product quality.

Key benefits include:

Cost Savings

Full-service metal part assembly delivers cost savings to customers by removing the need to coordinate with multiple suppliers or invest in in-house assembly facilities. It also reduces the risk of errors and rework during the assembly process.

Quality Control

As part of the full-service metal part assembly, rigorous quality control measures are employed to ensure that each component is accurately assembled and accurately. This helps maintain the highest standards of quality and consistency throughout the production process.

Efficiency

Working with a manufacturer that offers both fabrication and assembly services reduces lead times, minimizes transportation costs, and improves overall production efficiency. This accelerates time-to-market and reduces logistical complexities.

Versatility

This service can be applied across various industries, such as automotive, aerospace, electronics, and more, where complex metal components need to be assembled into finished products or subsystems.

Single Point of Contact

Rather than dealing with multiple suppliers, you deal with a single point of contact – the metal manufacturer – for both component fabrication and assembly, simplifying communication and project management.

Strategies for Integration

If you’re looking to integrate full-service metal assembly into your projects, it’s important to take a strategic approach that considers best practices depending on your industry.

For automotive projects, align the assembly process with stringent industry standards, emphasizing precision in joining sheet metal components. In aerospace applications, prioritize lightweight materials and employ advanced assembly techniques to meet stringent weight and performance requirements. For electronics, focus on precision machining and automated assembly processes to ensure the integrity of intricate metal parts.

Regardless of the industry, effective communication between engineering, manufacturing, and assembly teams is paramount to achieving seamless integration.

Pinnacle Precision: Masters of Mechanical Assembly

For businesses aiming to optimize project efficiency and cost-effectiveness, embracing full-service and electromechanical metal part assembly as part of your precision metal manufacturing is time. This comprehensive approach streamlines the manufacturing process, ensuring seamless integration of individual components and reducing the complexities associated with traditional assembly methods.

The team at Pinnacle has a long-standing history of excellence in full-service metal part assembly. Carefully considering everything from tolerances and alignment to functional requirements during manufacturing, our experienced assembly team ensures that every piece fits together flawlessly and performs its intended function with the utmost efficiency and durability.

Our comprehensive process meticulously joins and integrates individual sheet metal parts into a seamless, high-precision, and cohesive finished product.

Talk to us today for full-service metal part assembly that you can rely on.